How do you optimise Big Bag emptying?

Big Bags, also known as FIBCs (flexible intermediate bulk containers), are commonly used to store and transport bulk materials such as grain, minerals and chemicals. Yet unloading these bags is a complex and time-consuming task without proper equipment. This is where Big Bag emptying stations come in. But what is an emptying station? What are its advantages? What different types of emptying stations are there for Big Bags? In what industry sectors are they used? This article provides the answers to these questions.

Everything you ever needed to know about Big Bag emptying stations!

Big Bag emptying station: definition

A Big Bag emptying station is industrial equipment designed to facilitate the discharge of bulk bags, generally known as ‘Big Bags’ or ‘FIBCs’ (flexible intermediate bulk containers). Big Bags are large fabric or heavy-duty plastic containers used for transporting and storing bulk materials such as chemicals, cereals, minerals, foods, etc. The stations are designed to solve the challenge of unloading these materials in an efficient, safe and controlled manner.

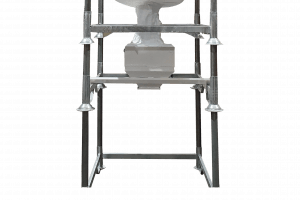

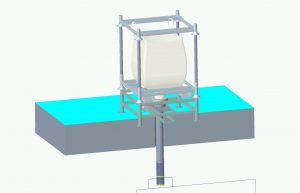

Emptying stations generally feature a robust structure with a frame for holding the bag, a lifting system for raising the bag and holding it in a vertical position, and an unloading mechanism allowing the materials contained in the bag to flow into a hopper, a conveyor or any other transport system in a controlled manner.

To sum up, a Big Bag emptying station is important industrial equipment that optimises the unloading of bulk materials contained in Big Bags. We will now review the key benefits of such stations.

Advantages of a Big Bag emptying station

The use of a Big Bag emptying station offers a number of advantages, making it a smart choice in many industries:

- Safety: Emptying stations are specially designed to minimise the risk of tipping or bulk material spillage during Big Bag handling. This guarantees operator safety since accidents due to handling heavy and potentially hazardous loads are limited.

- Efficiency: Compared with manual emptying, using an emptying station makes the process much faster and more efficient. It offers an automated solution for quickly emptying bag contents, and this can considerably speed up the production process.

- Waste reduction: Emptying stations are designed to ensure Big Bag emptying more fully, which means less material wastage. This is a clear benefit for both economic and environmental reasons.

- Regulatory compliance: Many industries are subject to stringent regulations regarding safety and the environment. Emptying stations are generally designed to meet these standards, thereby helping companies to comply with regulations and avoid penalties.

- Precision: Certain types of emptying stations, such as those equipped with diaphragm valves, allow precise flow control. This is crucial when specific flow rates are required for certain applications.

- Versatility: There are a variety of emptying stations suited to different materials, particle sizes and applications. This makes them versatile and adaptable to various different industries – from food, to construction to chemicals.

To sum up, Big Bag emptying stations improve safety, efficiency and regulatory compliance while reducing waste and offering more accurate flow control. This makes them a top choice for many companies that regularly handle bulk materials from Big Bags.

Types of Big Bag emptying stations

There is a wide range of Big Bag emptying stations. Each one is designed to meet specific needs depending on the type of materials, their particle size, flow control requirements and specific applications. Here are some examples of these stations:

- The emptying station with industrial slide gate valve, also known as a knife gate valve, provides emptying in one go and ensures basic flow control during the emptying process. It is particularly suited to large particle size materials (>6 mm), such as plastic granules, metals or minerals. Example of a custom-built emptying station with industrial slide gate valve.

- The emptying station with diaphragm valve is ideal for applications requiring precise flow control for materials. It uses a diaphragm to adjust valve opening, thus ensuring highly precise unloading. Additionally, certain stations of this kind offer the possibility of replacing the Big Bag during the emptying process, thus minimising downtimes. Example of a custom-built emptying station with electric diaphragm valve for a client in the agri-food sector.

- The emptying station with check valve (butterfly valve) allows unloading in one go as well as enabling the operator to roughly regulate the flow during emptying. It is suited to small particle size materials (<6 mm), such as powders and powdery products. It is commonly used in the chemical and mineral industries and cement production.

- The emptying station with flat bottom hopper and sleeve is very versatile. It can be used for a wide variety of bulk materials including granules, powders and powdery products. It uses a flat bottom hopper to stabilise the Big Bag and a sleeve for attaching the transfer system’s suction lance, allowing precise flow control. Example of an emptying station with flat bottom hopper and sleeve for a client in the plastic injection industry.

- The emptying station with seed valve is specially designed for the agricultural sector. It allows the controlled discharge of seed, granules or grain from Big Bags. It offers precise flow control to guarantee an even distribution of seed during crop planting.

In conclusion, the choice of appropriate emptying station will depend on the specific operational requirements and characteristics of the materials to be handled.

In what industry sectors are Big Bag emptying stations used?

Emptying stations are primarily for industrial usage. The aim is to empty the Big Bags in an efficient and controlled manner to render the contents usable or transformable in the production process. Below are some of the industry sectors that make use of Big Bag emptying stations:

- Chemical industry: bulk chemicals, whether in powder, granule or other form, are often packaged in Big Bags. Emptying stations are used to empty the bags and transfer the chemicals to production or mixing processes in total safety.

- Food industry: in food production, bulk ingredients such as flour, sugar, grains, spices, etc. are packaged in Big Bags. Emptying stations are used to unload these bags and supply production lines.

- Pharmaceutical industry: bulk pharmaceutical materials, including active chemical ingredients and excipients, are often stored in Big Bags. Emptying stations are used to transfer these materials to pharmaceutical manufacturing equipment.

- Plastics industry: bulk plastic resins are packaged in Big Bags. Emptying stations are used in the production of plastics to supply these materials to extrusion or moulding machines.

- Agriculture: farmers use Big Bags to store and transport bulk agricultural products such as seed, fertilizer, cereals, etc. Emptying stations facilitate material unloading for agricultural use.

- Mining industry: in the mining industry minerals and ores are often packaged in Big Bags. Emptying stations are used to unload these bags and supply mineral processing operations.

- Construction industry: on building sites bulk construction materials such as cement, sand and aggregate can be stored and transported in Big Bags. Emptying stations are used to empty these bags and supply building sites.

- Waste management: in the waste management sector, bulk waste can be packaged in Big Bags. Emptying stations facilitate bag unloading in waste treatment facilities.

In sum, Big Bag emptying stations are used in numerous industry sectors to facilitate the transfer of bulk materials packaged in Big Bags, and this improves the efficiency of production, treatment and storage processes.

Design & manufacturing of Big Bag emptying stations

Your trusted partner for custom-built emptying station development

ManuLine designs safe solutions for unloading materials from your flexible containers such as Big Bags and FIBCs quickly and without any spillage. Our Big Bag emptying stations are tailored for a wide range of both regular and occasional uses in different industry sectors.

- Technical expertise: ManuLine has 20 years’ experience in the design and manufacture of equipment for bulk handling operations.

- Customised design: ManuLine works closely with its clients to understand their specific requirements. Emptying stations are customised to best meet the characteristics of the materials, processes and operational requirements that are unique to each company.

- Quality: ManuLine uses the highest quality materials and exacting manufacturing standards to guarantee durable equipment. Our emptying stations comply with all application regulations.

- Customer service: ManuLine attaches great importance to customer satisfaction. We are on hand to answer any questions you may have and provide full monitoring of your projects.

To sum up, choosing ManuLine for the design and manufacture of your custom-built emptying station is your assurance of dealing with an experienced partner who is capable of meeting your specific needs, and your guarantee of equipment that is top quality and durable, and meets compliance regulations.

You can rely on ManuLine to optimise your bulk handling processes

You can trust ManuLine to improve your bulk material management operations. We provide cost-effective, customisable and flexible solutions that meet the requirements of various sectors such as agri-food, pharmaceuticals, engineering, chemicals, textiles, and many more, within the specific environment of each individual company.