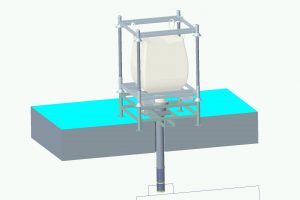

Custom-built emptying station with electric diaphragm valve (agri-food sector)

ManuLine recently offered one of its customers a custom-built emptying station tailored to the agri-food sector.

The customer needed to feed a machine located in a clean room (specific to food safety constraints) avoiding any contamination. The layout of the customer’s production area meant the Big Bag needed to be positioned on the upper floor, above this room. The customer was to carry out the work and drill the slab.

The emptying station developed for our customer can be used to unload various small-particle-size food products. We designed a containment system under the valve made from three elements:

-

-

- a stainless steel reducer,

- a rigid stainless steel tube,

- a food grade flexible hose.

-

This system is designed to protect against any external contamination of the product to be emptied. It also serves as a barrier to prevent the spread of the powdery material in the atmosphere.

To ensure quick and safe emptying, ManuLine offers an electric diaphragm valve. The valve can be controlled by the operator in the clean room thanks to a box with two press buttons. The flexible container is emptied by opening and closing the valve located on the outside of the Big Bag discharge chute.

This type of valve can be used to accurately and easily control the flow during emptying. The diaphragm valve is highly recommended in the agri-food sector as the Big Bag contents do not come into contact with the structure, preventing any risk of contamination. In addition, the flexible container can be emptied in several stages and can be replaced during emptying in the event of a change of product.

Ultimately, ManuLine is offering a completely custom-built solution to meet our customer’s expectations.

#New